PepsiCo has unveiled plans to introduce an automated storage and retrieval system at a warehouse in Grodzisk Mazowiecki, Poland.

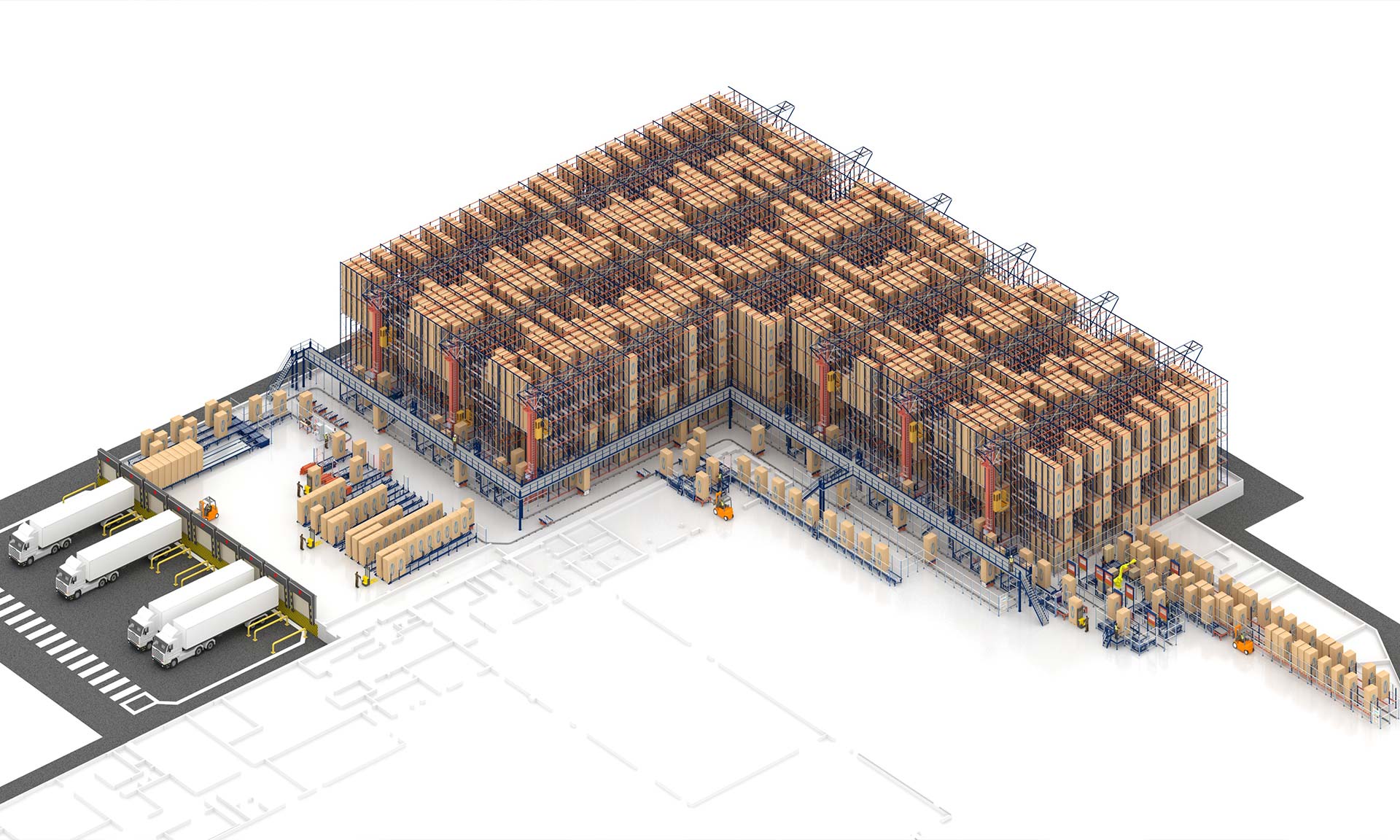

The smart warehouse will connect production and dispatch with an automated system from Mecalux, operating 24/7 in a bid to boost capacity and cut CO₂ emissions.

It features six stacker cranes serving racking equipped with the Automated Pallet Shuttle. They are equipped with an energy recovery system, saving between 15 per cent and 20 per cent in energy consumption with every movement.

The stacker cranes also incorporate an AI-powered computer vision system instead of traditional photocells, to support safer, more accurate pallet positioning.

Additionally, a floor-mounted electric monorail system and automatic conveyors will link the warehouse with the production lines, enabling a continuous, round-the-clock pallet inflow.

Connected to the production area, the system will accommodate the processing of crisps and other snacks.

“With this logistics automation project, production, the warehouse and dispatch will be automatically connected,” says Bartomiej Lesiuk, warehouse automation design manager at PepsiCo. “We’ve opted for a modular design that gives us the flexibility to adapt as our needs evolve.”

The move will mark the third warehouse project to incorporate the technology in Poland.

“With this new investment, we expect to optimise operations, expand warehouse capacity and lower logistics costs,” continued Lesiuk. “Automation will also allow us to make direct deliveries, avoiding double handling and unnecessary transport.

“On top of that, we estimate an annual reduction of 200 tonnes in greenhouse gas emissions.”

PepsiCo is one of the world’s largest snack food and beverage companies. Its extensive product range includes iconic brands such as Pepsi, Mirinda, Lay’s and Doritos.